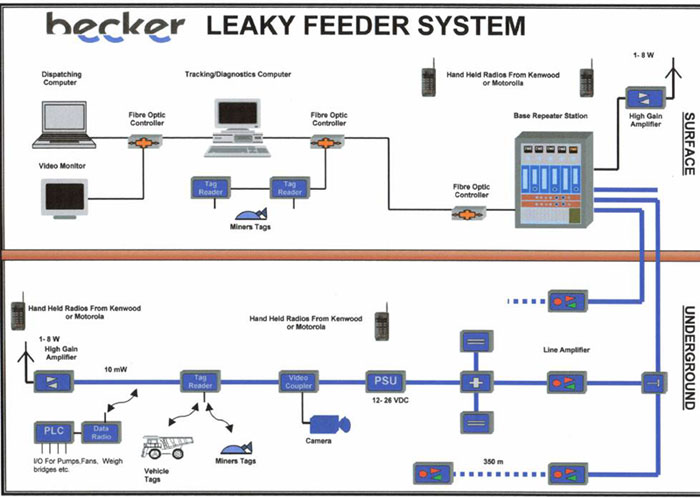

1. Konkola Copper Mines Underground Leaky Feeder Radio Communication

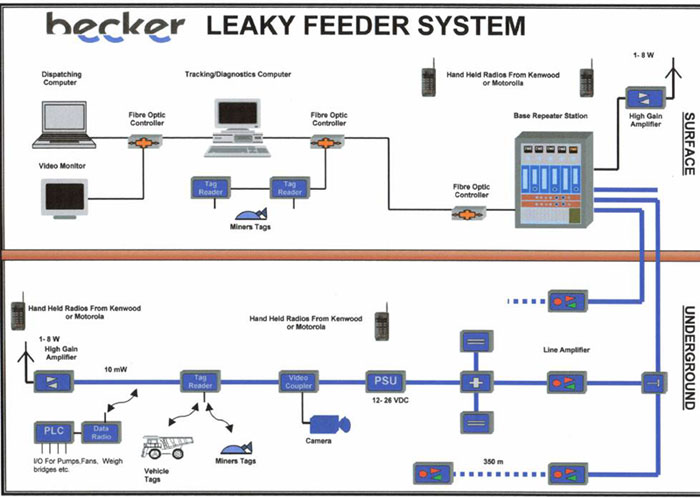

Fig 1.0

The above system was installed and commissioned at Konkola Copper Mines, Konkola Underground Mine by Field Tech Limited of Kitwe in December 20002 and is still being serviced by the same company since June 2004. The system is only being used on communication but is expandable and can be used for other applications such as telemetry, vehicle and manpower tracking etc.

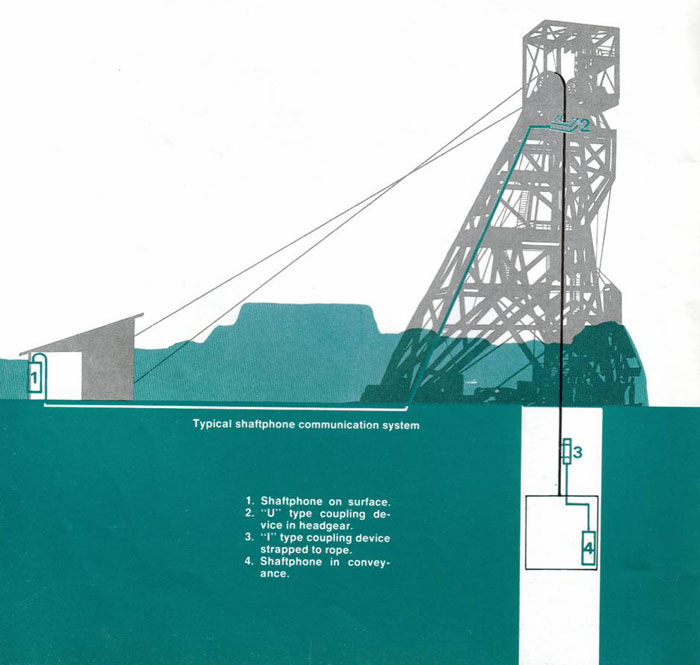

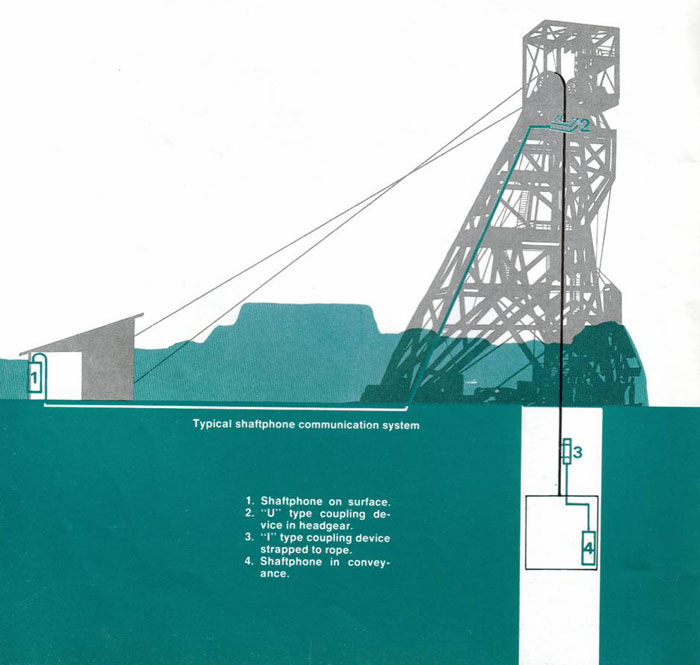

ECAM shaft phones installed and commissioned used for shaft inspection and communication.

The above systems were installed and commissioned at Konkola Copper Mines Plc at Konkola

and Nampundwe Mines in 2002 respectively and are being serviced and maintained by Field Tech Limited of Kitwe. Similar systems have been installed and commissioned at NFC Africa Mining of Chambishi Mine.

Most mines on the copperbelt are using this kind of communication for their shaft inspection and

for normal day to day shaft operations as a Statutory Requirement by Mine Safety Department

We did a similar installation for PROSEC AMCO of Kitwe during the installation pipes in the shaft through VS1B shaft of Konkola Mine 1 Shaft in Chililabombwe.

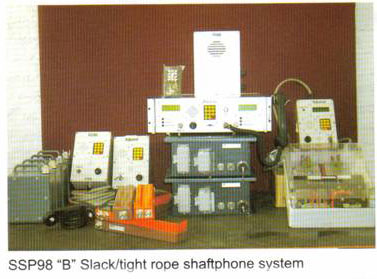

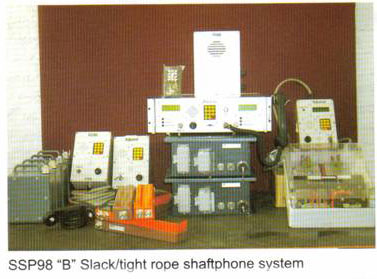

Slack and tight Rope Monitoring Systems, ECAM SSP 98 – B Single & Double Drum System

Installed and commissioned ECAM SSP98 – B Winder Slack and Tight Rope Monitoring systems

at Knokola and Nampundwe Mines in April 2002 and these systems are also being serviced and maintained by ourselves. We also attend to break downs on regular basis as problems occur to

keep the systems functional.

We also repaired standby Diesel Generator for the Bank of Zambia Ndola in September 2003.

which is still running and working perfectly well to date.

We repaired an Electronic Load Measurement Machine for Mckinnon Colombus Company of Kitwe used in the testing of chain blocks in February 2004.

Supply Voltage < 33KV, Six pulse, Air Cooled, thyrisitor Controlled Rectifier -25KA & 35KA

In September 2004 and March 2005, we were sub contracted by SAFTRONICS Company of South Africa in the installation and commissioning of the above 25KA and 35KA elect winning rectifiers at Mopani Copper Mines, Mufulira and Bwana Mkubwa Copper Mines of Ndola respectively.

DDH6, DC12, DC Drive - Exciter panels viewed with front panel open.

In October 2005, we supplied and successfully installed and commissioned six (6) DC exciter control panels on compressors and blowers at Mopani Copper Mines, Mufulira Power Plant. These

Drives have been in operation for a year now without any problems.

In October 2005, we repaired ECAM shaft phones at NFC Africa Mining Plc on the main winder.

We are yet to install and commission the new ECAM mintalk Shaft phones at the same mine sometime this year to improve on shaft communication as it has become a statutory requirement

by Mine Safety Department.

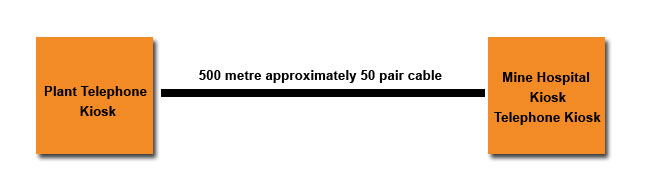

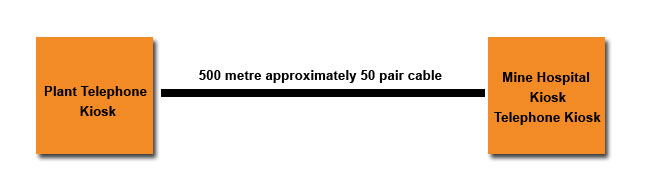

In November 2005, we repaired approximately 500 metres of 50 pair telephone cable network connecting Mufulira Mine Hospital and the plant at Mopani Copper Mines, Mufulira and commissioned the telecommunication between these two areas.

Mufulira Mine Plant & Hospital Sites.

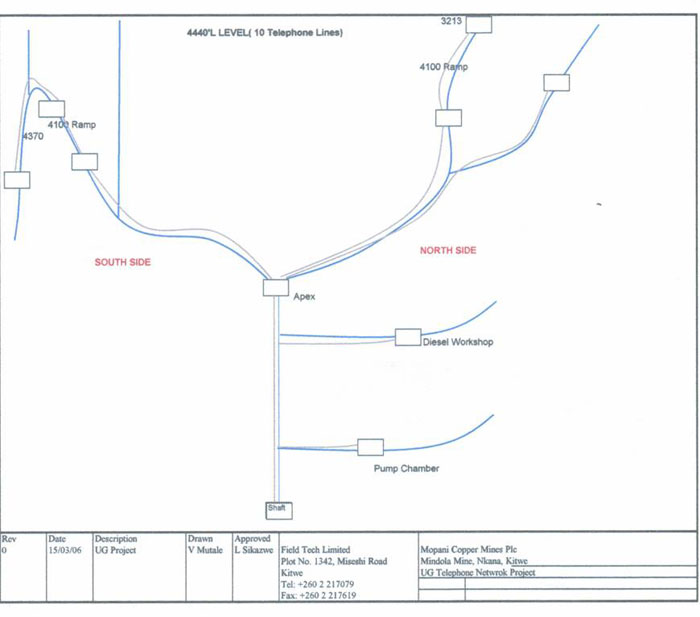

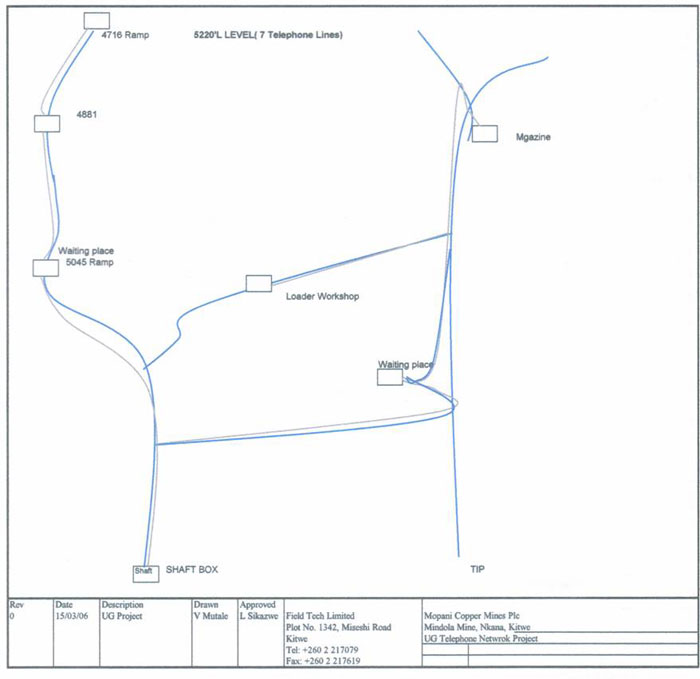

Mopani Copper Mines Plc – Nkana Mine

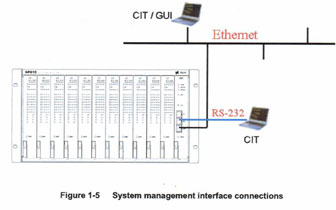

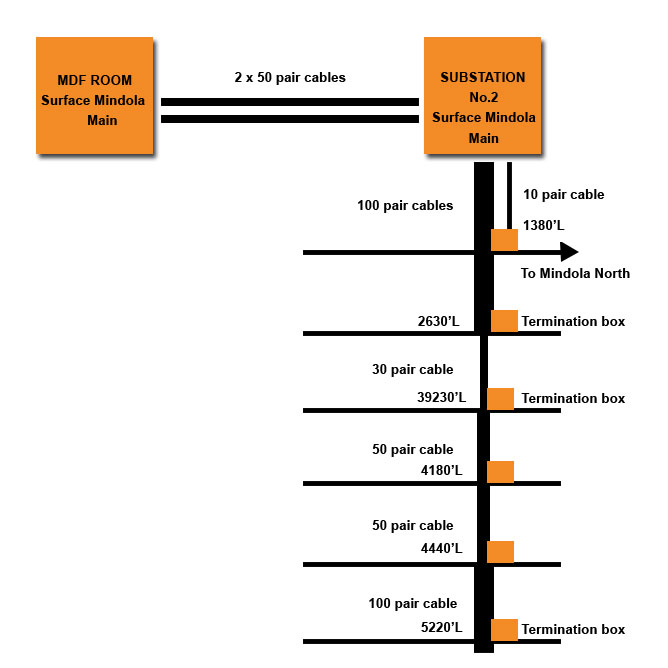

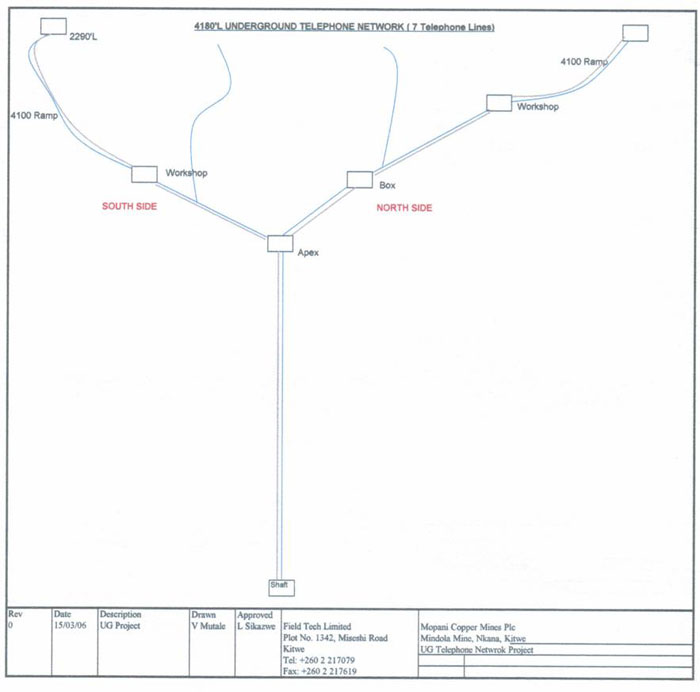

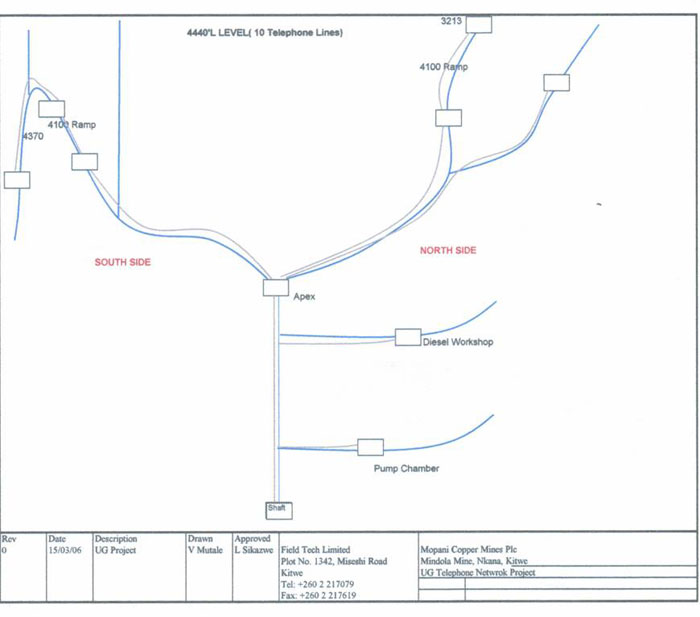

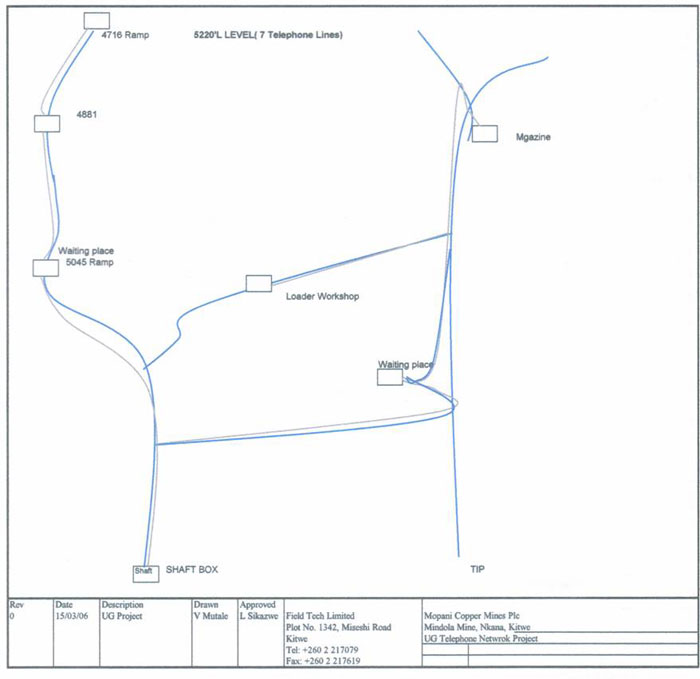

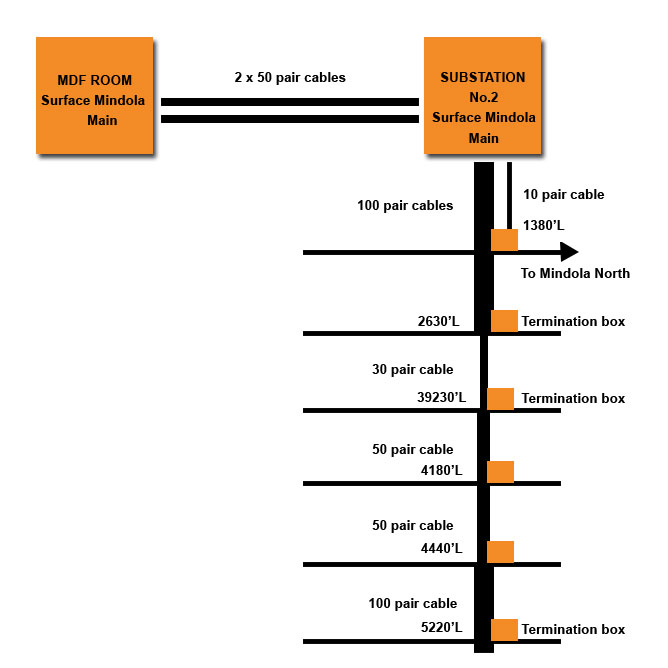

We are currently carrying out a project at Mopani Copper Mines Nkana Mine at Mindola Main

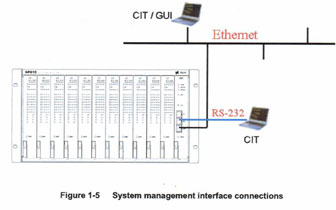

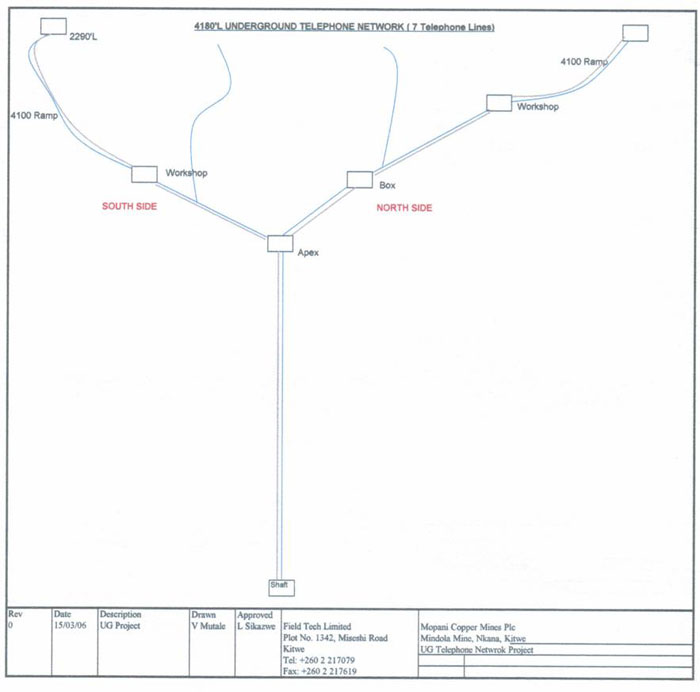

and North laying 9 x 50 pair cables at 1380’L haulage underground linking Mindola Main and North shafts. This involved connecting and commissioning of more than thirty – two telephone lines at various levels, 1380’L, 3920’L, 4180’L, 4440’L and 5220’L. The Underground telephone network is using a UMAP 3100 Enhanced Super Pair Gain (eSPG) Technology to enhance and make the system more economical. A single line carries 12 lines (Multiplexer) from COT to an RT unit (De-multiplexer) mounted underground through DSL 1 or 2

Surface COT interconnect within the MDF Room

Underground Telephone Cabling Linking Mindola Main & Mindola North

MINDOALA MAIN UNDERGROUND LEVEL 4180’ TELEPHONE CABLINING

MINDOLA MAIN UNDERGROUND LEVEL 4440’ TELEPHONE CABLING

MINDOLA MAIN UNDERGROUND LEVEL 5220’ TELEPHONE CABLINING

REMOTE UNITS – LINE UNITS (LU) UNDERGROUND

Most of our technicians and engineers have extensive experience in the installation and commissioning of electrical systems and process control instrumentation equipment having worked in the mining Industry for a number of years in excess of twenty.

We were the only Company in August 2006 to have been invited by Mopani Copper Mines Plc,

Nkana Central Shaft to tender for the installation and commissioning of Pump Chamber instrumentation equipment on Seven (7) Pumps at 2410’ and 3410’ levels underground at Mopani Copper Mines, Nkana Mine, and Central Shaft. We are awaiting the final award of

Contract being processed, and if awarded the contract, we hope and expect to complete this project within 50 days.

2. Component Supplies

The supply of materials, repairs and commissioning of new equipment at various companies by

our South African principal companies mentioned above is being done by ourselves and will be of

an ongoing nature and hence the appointment of Field Tech Limited to maintain, repair, service

and commission the supplied equipment locally in Zambia.

Major Clients

Mopani Copper Mines Plc, Mufulira Mine

Mopani Copper Mines Plc, Nkana Mine.

NFC Africa Mining Plc, Chambishi Mine

Konkola Copper Mines Plc; Konkola Mine,

Konkola Copper Mines Plc, Nchanga Mine

Konkola Copper Mines Plc, Nampundwe Mine

Chibuluma Mines Plc, Chibuluma South. |